Incorporating airlocks into your vegetable fermentation course of action opens the door to some globe of culinary delights. The managed ecosystem they offer makes certain prosperous and safe ferments, enabling you to savor the flavors of your favorite vegetables for extended.

So critical monitoring of air pressure upkeep is needed in all regions mainly because any drop or increase in the tension of any space might result in cross-contamination.

The strain In the bubble airlock is superior or optimistic and in adjacent sides, the pressure is much less or destructive.

The right collection and style and design of airlocks are very important to fulfill regulatory necessities and market benchmarks. By employing the right airlock systems and related systems, pharmaceutical companies can safeguard their producing processes and protect the overall health and nicely-remaining of clients who depend on their products.

In the event the differential stress within the airlock is in between The 2 adjoining rooms, an airflow is produced from the very best DP to the bottom DP, often called “cascading effect”.

In several analysis facilities, substances that are experimented on are really unsafe, and it is crucial to maintain them from staying uncovered. Through several types of output procedures within a clean home, air from the contaminated region should be contained in one location.

Fermentation is an excellent technique to make use of surplus vegetables, reducing meals squander click here and advertising sustainable foods methods.

Air showers use high-velocity air jets to blow away dust or other contaminants, making sure that only clean up resources are introduced in to the cleanroom.

While some swear via the simplicity of open jar fermentation, the potential risk of contamination is larger. Airlock-aided fermentation provides a more controlled atmosphere, decreasing the likelihood of spoilage.

Product airlocks also referred to as products transfer airlocks, are meant to transfer elements, devices, or samples in between different cleanroom environments or amongst cleanse and non-clear areas.

four. Interlocking Doorways: Installing interlocked doors can more info be a significant structure characteristic. These doors protect against either side of your airlock from getting opened at the same time, which could disrupt the force differential and permit contaminants to move involving rooms. This is very critical for maintaining the integrity of high-containment or sterile spots.

By developing managed environments with stress differentials, airlocks allow for for your Safe and sound movement of personnel and materials without the need of compromising the cleanliness or safety of sensitive production zones.

This has to be made to aid for working with Are living cells and inactivated products and solutions which desires rigid containment & Regulatory problems for both of those personnel protection and cross contamination among parts and merchandise.

This prevents to entry dust and contamination from exterior to airlock and from airlock to interior side.

Michelle Pfeiffer Then & Now!

Michelle Pfeiffer Then & Now! Romeo Miller Then & Now!

Romeo Miller Then & Now! Andrea Barber Then & Now!

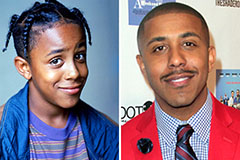

Andrea Barber Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! Richard Thomas Then & Now!

Richard Thomas Then & Now!